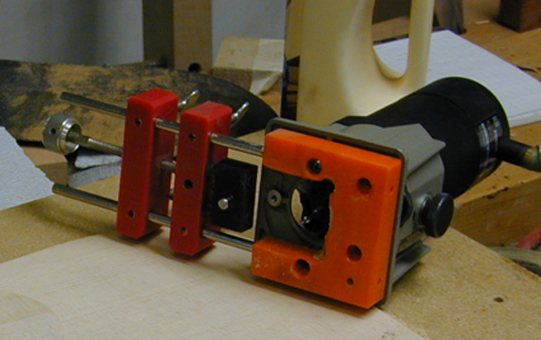

Greg I just made a base for a dremel and use Stew Mac down cut spirals, I have gotten fantastic results. I can adjust the diametre of cut using my digital calipers and referencing off the plates on the bottom of the base, I can get with a couple of thou! Here is a picture, aluminum, maple and mahogany, all of which you can cut with you woodworking tools, at least I did. I have since added some mac-tac to the bottom of the bases to keep the oxidizing aluminum off of the wood surfaces.

I think I posted an earlier thread on this little device but I can help you out if you want to make one.

Good Luck

Shane

!

!